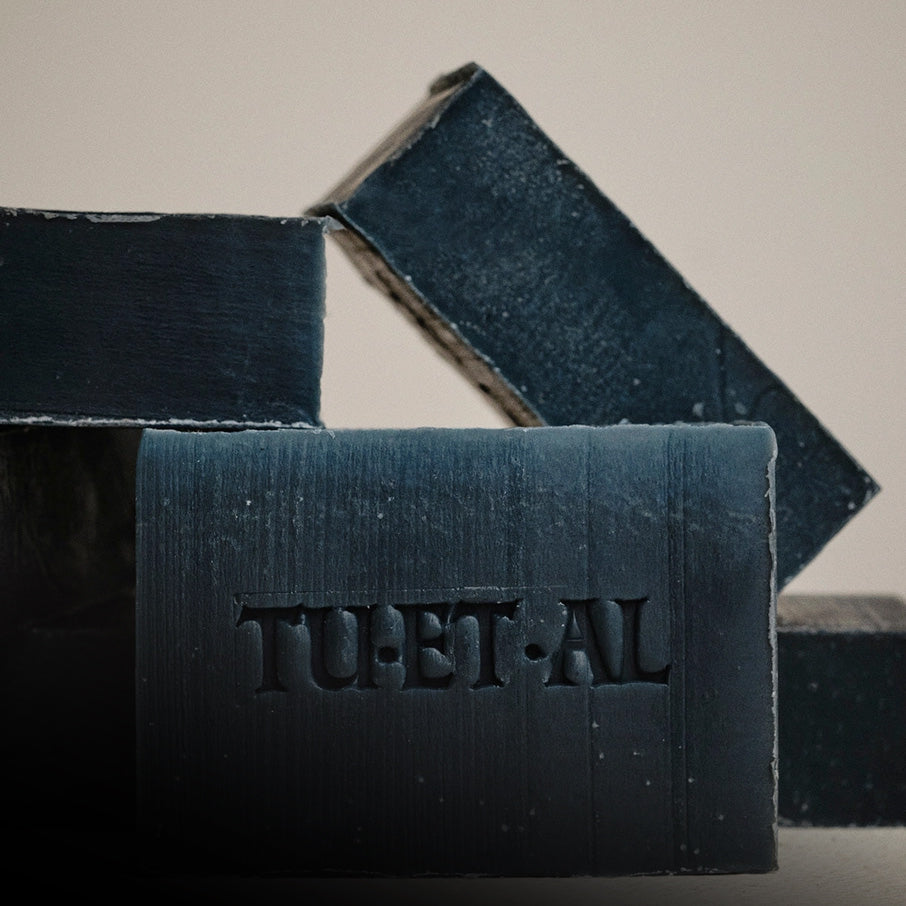

Today, we would like to share an update on the wooden boxes.

We spoke to Erik last week, and he said that he is currently able to work in his shop 4 nights a week for one or two hours each night. The next round of boxes will be completed in December. This round should take us through backer number 100.

While Erik was making the boxes, he ran into trouble with the wood warping which made it difficult to complete the boxes that were almost finished. So, he paused making the boxes and took time to climate control his workshop. Now humidity and temperature swings won't warp the wood as much.

To further help with the warping, instead of milling the wood in one pass, he does it in two passes. After the first pass, he clamps the wood flat and waits a week to relieve the stress and humidity. He then mills the wood again to remove any warping that occurred.

Here are the 13 steps that Erik takes to create the boxes. He is currently on step 12 with the next batch.

-

Milling the wood

-

Sizing all the pieces

-

Cutting the matching grain with a 45 degree cut

-

Cutting the box joints

-

Engraving the tops

-

Sanding the inside faces

-

Drilling holes for magnets/hinges and gluing the magnets in place

-

Gluing the boxes together

-

Sanding the outside

-

Rounding the corners

-

Hand sanding the boxes

-

Final tweaks (mostly manual sanding for lids that are too tight or pinching parts from movement)

-

Finishing (coating the boxes with lacquer)

Once your box is ready to ship, we will send you an email to confirm and update your address. Then you will receive an email with your tracking number once the box is on the way.

Please let us know if you have any questions. We appreciate your patience as Erik completes your box.

William Rader

Krisztina Kondor